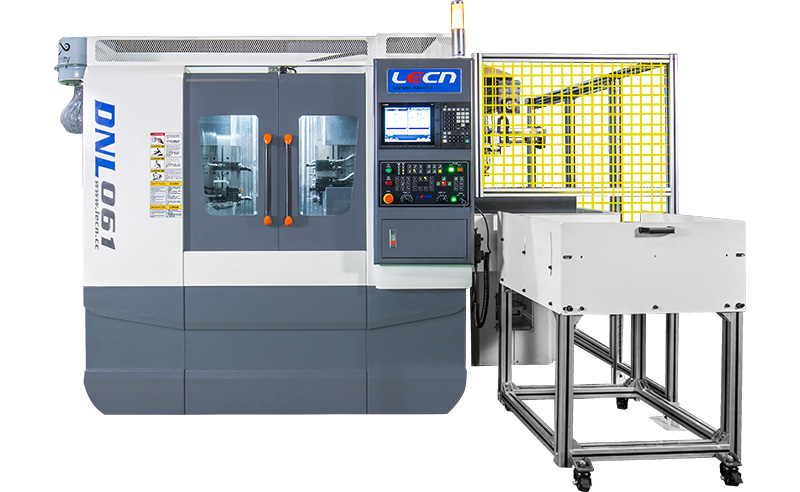

Unveiling Precision Engineering: The 6-Axis 8-Module CNC Gear Hobbing Machine

The world of industrial manufacturing has been revolutionized by the introduction of the 6-axis 8-module CNC gear hobbing machine. This marvel of engineering has significantly advanced the production of gears and has become the cornerstone of various industries requiring high-precision gear manufacturing.

Advanced Precision:The 6-axis capability combined with 8 modules brings unparalleled precision to gear cutting. This CNC machine performs an array of operations with incredible accuracy, resulting in gear teeth that are geometrically precise and consistent.

Versatility in Production:The multi-axis configuration allows for the production of various types of gears—spur, helical, bevel, and more. Its adaptability and flexibility in operation enable it to cater to a wide range of gear-cutting needs.

Enhanced Efficiency and Productivity:By combining eight modules, the machine significantly reduces setup time and enhances overall efficiency. It optimizes the production process, allowing for faster turnaround times and increased productivity.

Additional resources:

Screwdriving Robot: Revolutionizing Industrial Automation

How does oil extraction machines work?

Inline Plastic Scrap Granulator: A Revolutionary Solution for Plastic Waste Recycling

X-ray Counter: Revolutionizing Medical Imaging

Enhancing Efficiency and Precision: The Advantages of CNC Pipe Threading Lathes

Understanding the Pricing Factors of Portable Pipe Cutting Machines

What is Colour Coated Steel?Cutting-Edge Technology:This CNC gear hobbing machine is equipped with cutting-edge technology, including the latest controls and software systems that ensure a seamless and precise gear manufacturing process.

Industry Applications:From automotive to aerospace industries, this machine is instrumental in manufacturing gears that meet stringent quality standards. It is also vital in other sectors like robotics, heavy machinery, and marine engineering.

Quality Assurance:The precision and accuracy of the 6-axis 8-module CNC gear hobbing machine contribute to creating gears of the highest quality, ensuring reliability and longevity in their applications.

In conclusion, the 6-axis 8-module CNC gear hobbing machine stands as a pinnacle of precision engineering. Its cutting-edge technology, multifunctional capabilities, and unrivaled precision make it an indispensable tool in the manufacturing of high-quality gears across various industries.

What are the applications of waste heat boilers?

Unlocking Precision and Efficiency: How Fiber Laser Cutting Machines Work

Mushroom Grinding Machine: Revolutionizing the Processing Industry

Fixed Towing Cableways as a Transport Solution

What are the advantages of using a microbulk tank?

How Do I Choose the Right Low-Pressure Injection Molding Machine for My Needs?

Air-Cooled Screw Condensing Units

269

0

0

Related Articles

-

272

0

0

-

289

0

0

-

342

0

0

-

318

0

0

-

304

0

0

-

322

0

0

-

317

0

0

-

330

0

0

Comments

All Comments (0)