How Are The Chips Packing Machine Working?

How Are The Chips Packing Machine Working?

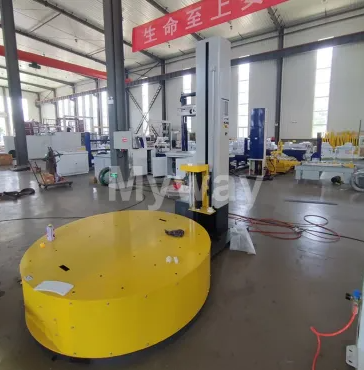

Packaging machine in the packaging industry, can change the way the packaging process action and packaging containers and materials processing methods, to achieve automatic control packaging system, can greatly improve production efficiency and product quality, and eliminate the error of the packaging process and printing label, etc, effectively reduce the labor intensity of workers, and reduce the consumption of energy and resources.

Role of the packaging machine

The packaging machine is the product packaging up a kind of machine, to protect, beautiful role. The packaging machine is mainly divided into two aspects:

1. Assembly line type overall production packaging.

2. Peripheral packaging equipment.

Application of packaging machine

Assembly line production packaging, applied to food, medicine, daily chemicals, hardware, lighting, furniture and other industries (bag, bottle) product filling (filling), sealing machine, code.

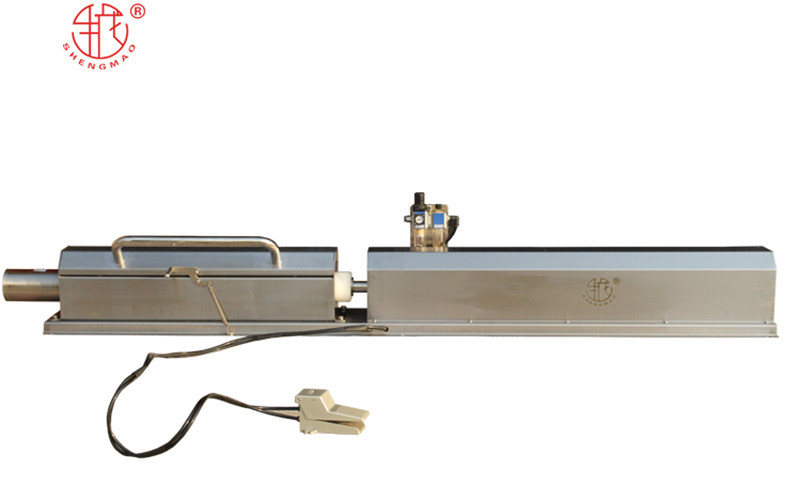

It mainly includes: liquid (paste) filling machine, pillow type packing machine, horizontal type packing machine, vertical type packing machine, powder particle packing machine, bag type automatic packing machine, frozen products automatic packing machine, etc.

Packaging machine classification

There are many kinds of packing machines and many classification methods. From different points of view there can be a variety of, according to the types of machinery: liquid packaging machine, powder packaging machine, particle packaging machine, stick packaging machine, sauce packaging machine, electronic combination scale packaging machine, pillow packaging machine; According to the role of packaging, there are inner packaging, outer packaging machine; According to the packaging industry, food, daily chemicals, textiles, and another packaging machine; According to the packaging station, there are simplex, multi-station packaging machine; According to the degree of automation, semi-automatic, automatic packaging machine.

The vacuum packing machine is divided into a horizontal vacuum packing machine and a vertical vacuum packing machine. The object to be packed in the horizontal vacuum packing machine is placed horizontally; The object of the vertical vacuum packing machine is placed vertically. Horizontal vacuum packing machines are more common on the market.

filling machine

A filling machine is a packing machine which loads the exact amount of packing goods into various containers. The main types are:

Volume filling machine. Including measuring cup type, intubation type, plunger type, material level type, screw type, timing type filling machine.

Weighing type filling machine. Including intermittent weighing type, continuous weighing type, weighing - centrifugal and another fractional filling machine.

Additional resources:How long does ozone treatment for car take?

What does a bucking unit do?

Advantages of Mobile Asphalt Plants

The Differences Between Barrel and Rack Plating

The Versatile Products of Blow Molding: A Comprehensive Guide

What is the difference between a boom lift and a spider lift?

What is a cableway used for?

Counting type filling machine. Including single counting type, multi - counting type filling machine.

Automatic Meat Roll Filling Machine

sealing machine

A sealing machine is a machine that seals the container filled with packing materials. Its main types are:

No sealing material sealing machine. Including hot - pressing, cold - pressing, fusion - welding, plugin, folding sealing machine.

There is a sealing material sealing machine. Including rotary type, rolling type, edge type, pressure type, and other sealing machines.

There are auxiliary sealing materials sealing machine. Including adhesive tape, bonding type, nailing type, ligation type, suture type, and another sealing machine.

The process of automatic packaging

The first and most important step in achieving packaging automation is to define the process. A quality work project is based on the characteristics of the process, not the automation equipment to determine the final design. The three key factors to consider in defining this process are the form of product and packaging structure, the amount of production, and the labor force.

This is the working principle of the automatic packaging machine, as well as the packaging process, automatic packaging attention to the above considerations can be.

Please contact us to get more details about the machines.

How much does a fiber laser cutter cost?

How does a golf ball making machine work?

Good Quality And Can Be Customized, Suncenter's High-flow Nitrogen Booster Equipment was Well Received

Electric Forklifts vs. Diesel Forklifts: Understanding the Key Differences

Understanding the Die Cutting Process in Custom Packaging

Exploring the Benefits of an 80C High Temperature Heat Pump Water Heater

What should you pay attention to when using a Gold Melting Furnace

225

0

0

Related Articles

-

275

0

0

-

297

0

0

-

338

0

0

-

378

0

0

-

618

0

0

-

286

0

0

-

294

0

0

-

263

0

0

Comments

All Comments (0)