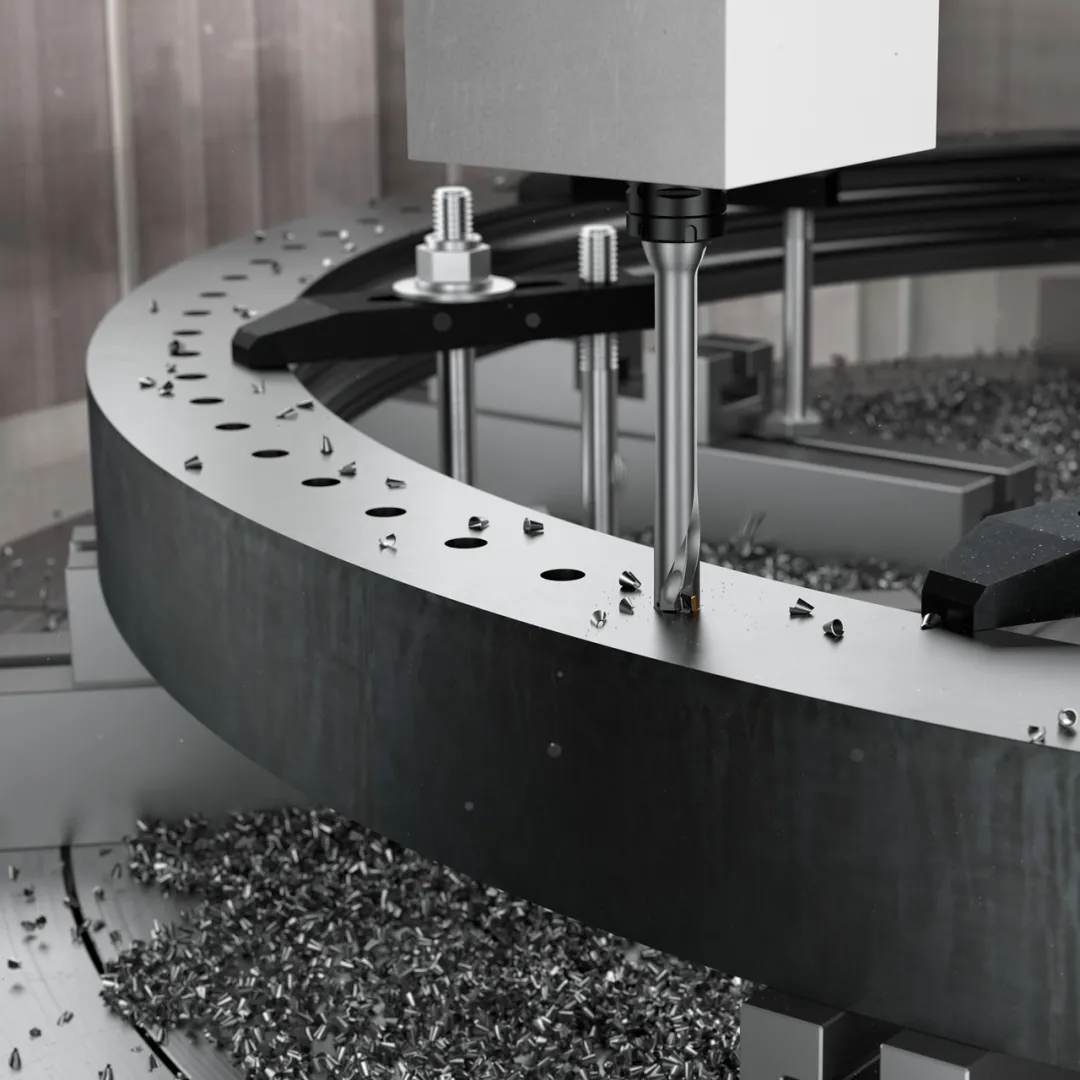

Best deep hole drilling techniques for purchasing decisions?

Apr. 05, 2024

When it comes to purchasing decisions for deep hole drilling techniques, it is essential to consider a few key factors to ensure that you are getting the best value for your money. The best deep hole drilling techniques for purchasing decisions are those that are cost-effective, efficient, and produce high-quality results.

One of the most important considerations when choosing deep hole drilling techniques is cost-effectiveness. It is essential to find a technique that provides a good balance between cost and performance. This means looking for techniques that offer high productivity and efficiency while also being affordable. Some cost-effective deep hole drilling techniques include gun drilling, BTA drilling, and EDM drilling.

Another crucial factor to consider when making purchasing decisions for deep hole drilling techniques is efficiency. The technique you choose should be able to produce accurate and precise results quickly and consistently. This will help minimize downtime and increase productivity. Techniques such as gundrilling, which uses a single flute drill to produce deep holes with high accuracy, are highly efficient and can significantly improve workflow.

Complete classification of CNC machine tools

Mastering the Art of Deep Hole Drilling

Top 10 Tips for Maximizing Efficiency with CNC Cylindrical Grinding Machine

Mastering Precision: Centerless Grinding Machines Unleashed

10 Surprising Applications of Grinding Machines for Ultimate Precision

Why Choose Cage Internal Grinding Machine Now?

Unlocking the Mysteries of Lecn: Your Ultimate Guide Revealed!

In addition to cost-effectiveness and efficiency, the quality of the results produced by the deep hole drilling technique is also essential. High-quality results are crucial for ensuring that the parts being produced meet the required specifications and standards. Techniques such as BTA drilling, which uses a special tool to improve chip control and produce high-quality results, are ideal for applications that require tight tolerances and superior surface finishes.

Overall, the best deep hole drilling techniques for purchasing decisions are those that offer a good balance between cost-effectiveness, efficiency, and quality. By considering these factors when choosing a drilling technique, you can ensure that you are getting the best value for your money and that your parts are being produced to the highest standards. Make sure to do thorough research and consider all available options before making a decision to ensure that you are making the right choice for your specific needs.

If you are looking for more details, kindly visit 3 roller bending machine, cnc turning operations, slot cutting machine.

Additional resources:Ultimate Guide: Rolling Machine Diagram Explained Simply

4 Advice to Choose a Two Roll Bending Editor's note: Don't forget to include specific details related to two roll bending in your blog post!

Ultimate Guide to Cylindrical Machines: Everything You Need to Know

How Does 3D printing Work?

How Does CNC milling machine Work?

How to Choose a Facing Machine

10 Questions You Should Know about Customized CNC Lathe Parts

134

0

0

Related Articles

-

131

0

0

-

How to optimize CNC machine turning operation?

Are you looking to optimize your CNC machine turning operation?

104

0

0

-

130

0

0

-

152

0

0

-

92

0

0

-

91

0

0

-

95

0

0

-

92

0

0

Comments

All Comments (0)