Mastering External Cylindrical Grinding Machines with Ease

Mar. 27, 2024

LECN contains other products and information you need, so please check it out.

Mastering External Cylindrical Grinding Machines with Ease.

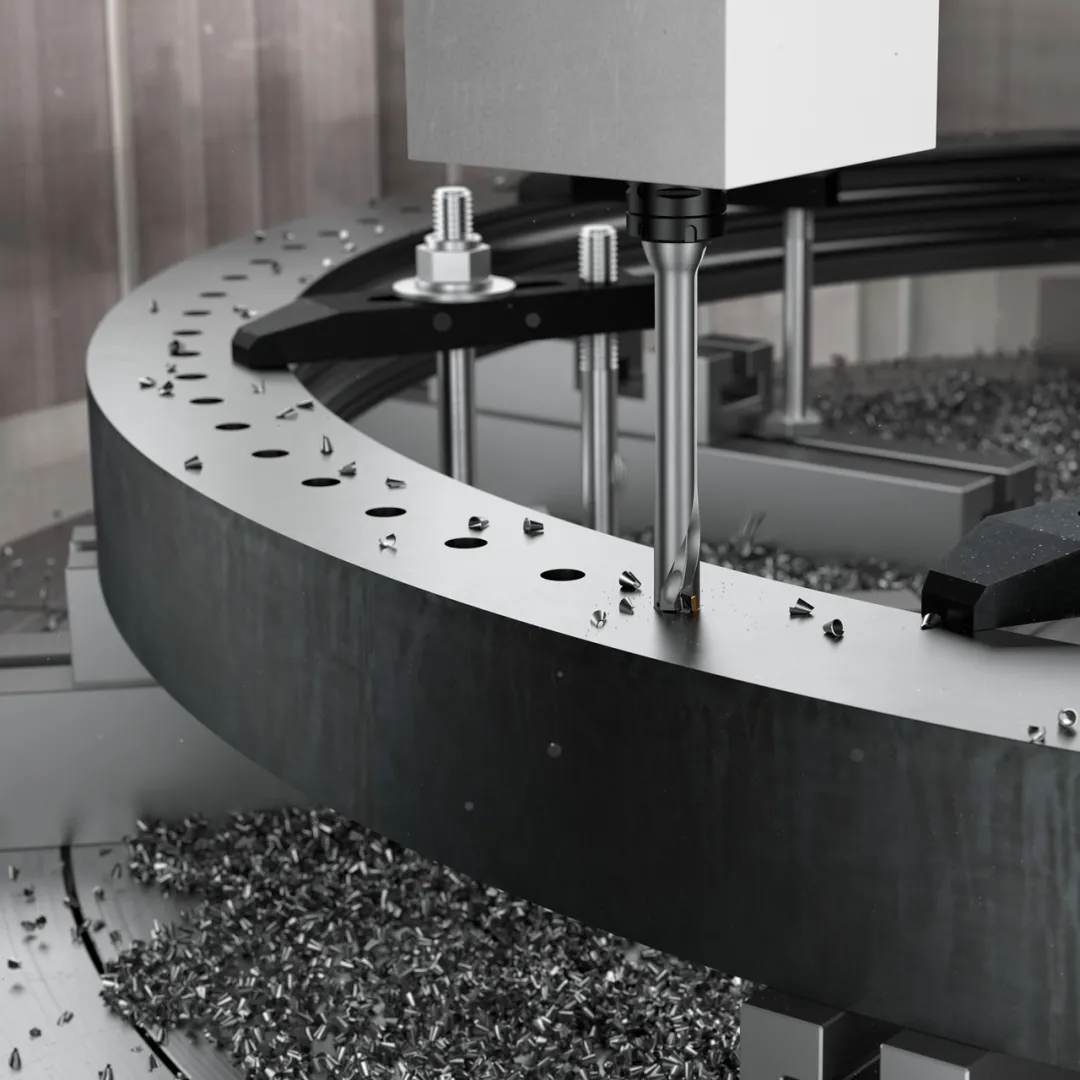

External cylindrical grinding is a crucial process in the manufacturing industry. It is used to produce precision parts with high levels of accuracy and surface finish. Mastering the operation of external cylindrical grinding machines is essential for any machinist or manufacturer looking to produce high-quality components efficiently. In this article, we will explore some tips and techniques to help you master external cylindrical grinding machines with ease.

Understanding the Basics of External Cylindrical Grinding Machines.

External cylindrical grinding machines are used to grind the outer surface of a workpiece. The machine consists of a rotating grinding wheel that removes material from the workpiece to achieve the desired shape and surface finish. The workpiece is mounted on a spindle and rotated against the grinding wheel to produce a precision finish. Understanding the basic components and operation of the machine is critical to achieving optimal results.

Setting Up the Machine.

Proper machine setup is essential for achieving accurate and consistent results in external cylindrical grinding. This includes ensuring that the workpiece is securely mounted on the spindle and aligned correctly with the grinding wheel. The machine settings, such as wheel speed, feed rate, and depth of cut, must also be adjusted to suit the material being ground and the desired finish. Taking the time to carefully set up the machine will pay off in the form of higher-quality components.

Choosing the Right Grinding Wheel.

Selecting the correct grinding wheel is crucial for achieving the desired surface finish and material removal rate. Different materials and workpiece geometries require specific types of grinding wheels to produce optimal results. Factors such as wheel diameter, abrasive material, grit size, and bond type must be considered when choosing a grinding wheel. Experimenting with different wheels and settings will help you determine the best combination for your specific application.

Additional resources:Complete classification of CNC machine tools

Best deep hole drilling techniques for purchasing decisions?

Mastering the Art of 3 Roll Bending

Mastering the Art of Deep Hole Drilling

Top 10 Tips for Maximizing Efficiency with CNC Cylindrical Grinding Machine

Mastering Precision: Centerless Grinding Machines Unleashed

10 Surprising Applications of Grinding Machines for Ultimate Precision

Optimizing Grinding Parameters.

Optimizing grinding parameters such as wheel speed, feed rate, and depth of cut is essential for achieving efficient material removal and surface finish. Adjusting these parameters based on the material being ground, workpiece geometry, and desired finish will help you achieve the best results. Keep track of the machine settings and results to identify trends and make continuous improvements to your grinding process.

Maintaining the Machine.

Regular maintenance of external cylindrical grinding machines is essential to ensure optimal performance and longevity. This includes cleaning the machine, inspecting and replacing worn components, and verifying the accuracy of the machine settings. Proper maintenance will help prevent costly downtime and ensure that your machine continues to produce high-quality components consistently.

Conclusion.

Mastering external cylindrical grinding machines requires a combination of knowledge, skill, and experience. By understanding the basics of machine operation, setting up the machine correctly, choosing the right grinding wheel, optimizing grinding parameters, and maintaining the machine, you can achieve excellent results with ease. Taking the time to learn and practice these techniques will help you become a proficient operator of external cylindrical grinding machines.

Contact Us.

If you have any questions or would like to learn more about mastering external cylindrical grinding machines, please do not hesitate to contact us. Our team of experts is here to help you achieve success in your grinding operations.

Contact us to discuss your requirements of roll bending. Our experienced sales team can help you identify the options that best suit your needs.

Additional resources:Why Choose Cage Internal Grinding Machine Now?

Unlocking the Mysteries of Lecn: Your Ultimate Guide Revealed!

Ultimate Guide: Rolling Machine Diagram Explained Simply

4 Advice to Choose a Two Roll Bending Editor's note: Don't forget to include specific details related to two roll bending in your blog post!

Ultimate Guide to Cylindrical Machines: Everything You Need to Know

How Does 3D printing Work?

How Does CNC milling machine Work?

116

0

0

Related Articles

-

106

0

0

-

132

0

0

-

131

0

0

-

How to optimize CNC machine turning operation?

Are you looking to optimize your CNC machine turning operation?

104

0

0

-

130

0

0

-

152

0

0

-

97

0

0

-

101

0

0

Comments

All Comments (0)