Mastering the Art of 3 Roll Bending

Apr. 07, 2024

## Mastering the Art of 3 Roll Bending.

1. What is 3 roll bending?

2. What are the key factors for mastering the art of 3 roll bending?

## What is 3 roll bending?

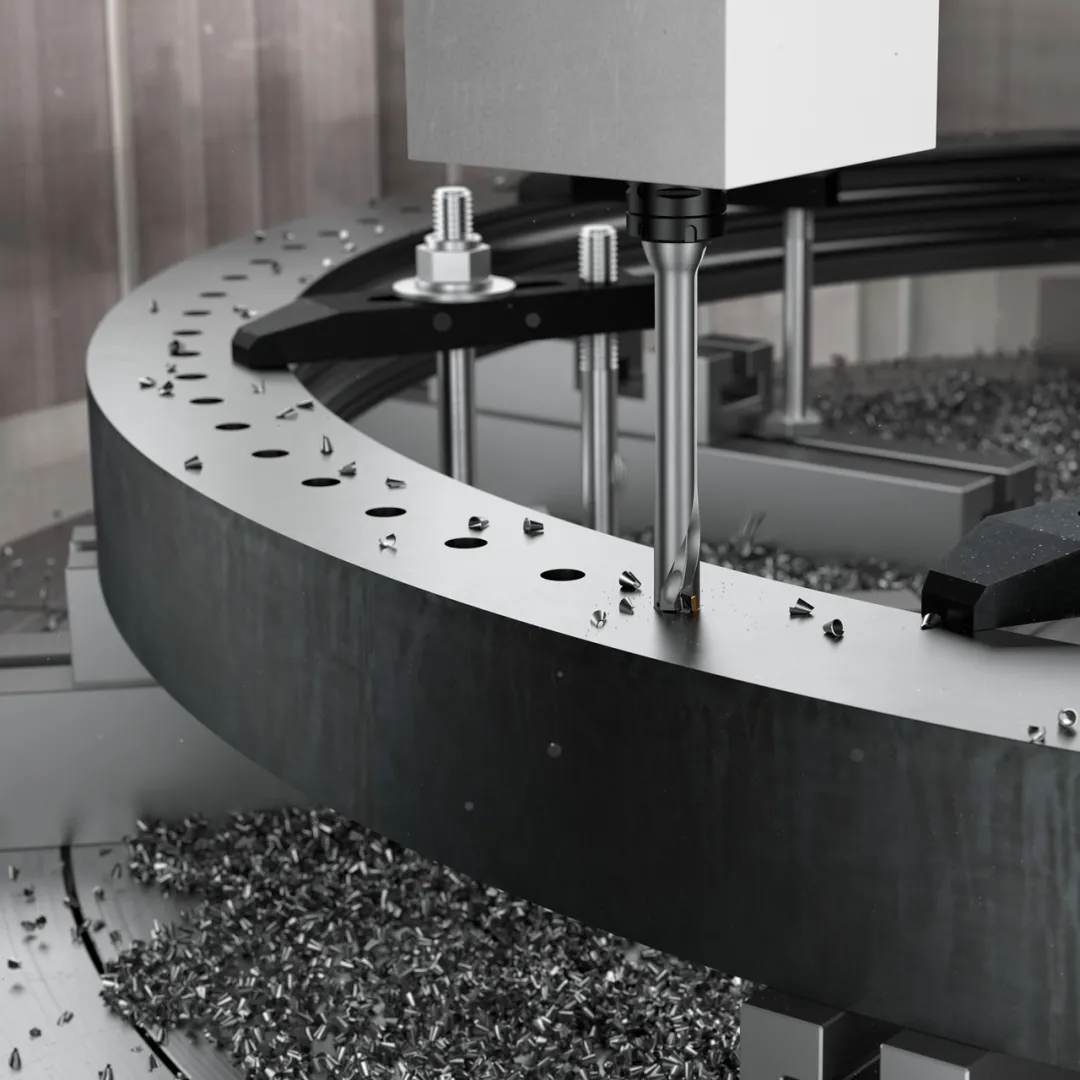

3 roll bending is a metal forming process where a sheet or plate is passed through a series of rollers to bend it into a desired shape. The rollers are positioned in a triangular configuration, with one roller at the top and two at the bottom. As the sheet passes through the rollers, it is gradually bent into the desired curvature.

## What are the key factors for mastering the art of 3 roll bending?

Additional resources:Complete classification of CNC machine tools

Mastering the Art of Deep Hole Drilling

Top 10 Tips for Maximizing Efficiency with CNC Cylindrical Grinding Machine

Mastering Precision: Centerless Grinding Machines Unleashed

10 Surprising Applications of Grinding Machines for Ultimate Precision

Why Choose Cage Internal Grinding Machine Now?

Unlocking the Mysteries of Lecn: Your Ultimate Guide Revealed!

1. Material selection: Choosing the right material is essential for successful 3 roll bending. The material should have good formability and be able to withstand the bending process without cracking or tearing.

2. Machine setup: Proper machine setup is crucial for achieving accurate and consistent bends. The distance between the rollers, their alignment, and the pressure applied during bending all play a role in determining the quality of the final product.

3. Operator skill: Skilled operators are key to mastering the art of 3 roll bending. They must have a good understanding of the bending process, as well as the ability to make adjustments on the fly to ensure the desired outcome.

4. Quality control: Regular inspections and measurements are important for maintaining the quality of the bent parts. Checking for defects, such as wrinkles or flat spots, and making necessary adjustments will help achieve the desired results.

5. Training and practice: Practice makes perfect when it comes to mastering 3 roll bending. Operators should undergo thorough training and gain hands-on experience to become proficient in this metal forming technique.

By focusing on these key factors, manufacturers can improve their 3 roll bending process and produce high-quality, accurately bent parts for a variety of applications.

Contact us to discuss your requirements of rolling bending machine, parts of cylindrical grinding machine, cnc turning operations. Our experienced sales team can help you identify the options that best suit your needs.

Additional resources:Ultimate Guide: Rolling Machine Diagram Explained Simply

4 Advice to Choose a Two Roll Bending Editor's note: Don't forget to include specific details related to two roll bending in your blog post!

Ultimate Guide to Cylindrical Machines: Everything You Need to Know

How Does 3D printing Work?

How Does CNC milling machine Work?

How to Choose a Facing Machine

10 Questions You Should Know about Customized CNC Lathe Parts

140

0

0

Related Articles

-

131

0

0

-

How to optimize CNC machine turning operation?

Are you looking to optimize your CNC machine turning operation?

104

0

0

-

130

0

0

-

152

0

0

-

77

0

0

-

88

0

0

-

92

0

0

-

93

0

0

Comments

All Comments (0)