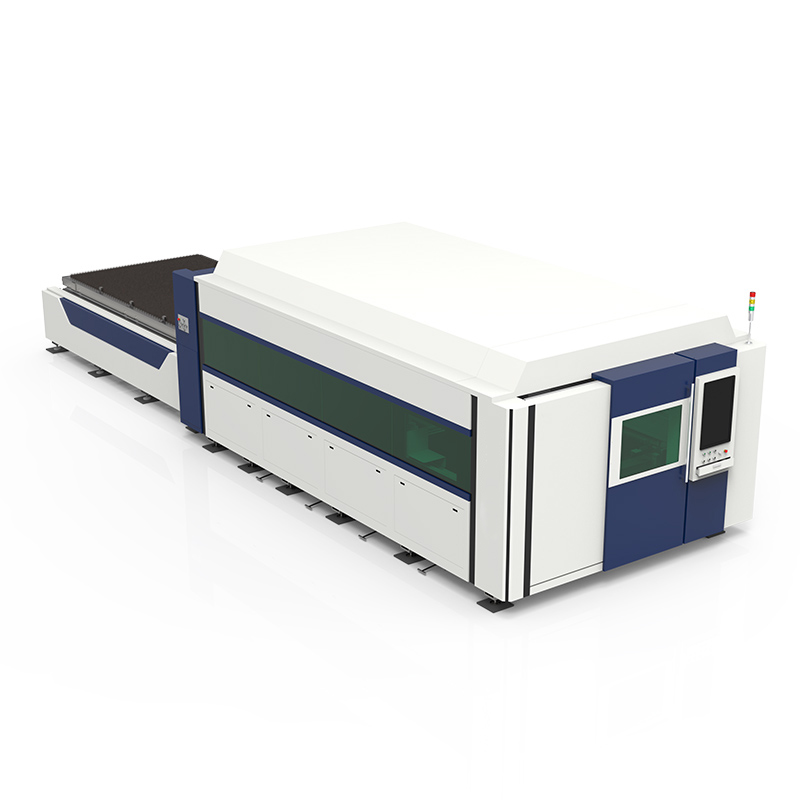

Why is Laser Cutting a Good Fit for Sheet Metal Fabrication?

Laser cutting has established itself as an exceptionally well-suited technology for sheet metal fabrication, offering a multitude of advantages that make it an indispensable tool in this field. Its unique combination of precision, efficiency, versatility, and quality makes it a good fit for various aspects of sheet metal fabrication. Let's delve into why laser cutting stands out as a preferred choice for shaping and manipulating sheet metal.

Unmatched Precision: One of the most remarkable features of laser cutting machine is its precision. The focused laser beam is guided by computer-controlled systems, ensuring accurate cuts that leave minimal room for errors. This precision is particularly valuable when working with intricate designs and tight tolerances, allowing for the creation of complex shapes and patterns on sheet metal with extraordinary accuracy.

Speed and Efficiency: Laser cutting is synonymous with efficiency. The high-energy laser beam melts or vaporizes the material it touches, resulting in rapid and clean cuts. This speed is especially advantageous when dealing with high-volume production runs, enabling manufacturers to meet tight deadlines without compromising on quality.

Versatility in Material Selection: Sheet metal fabrication involves working with various materials, from stainless steel and aluminum to brass and copper. Laser cutting's versatility shines as it can effectively handle an array of materials, thanks to adjustable settings that cater to each material's unique properties. This adaptability minimizes the need for multiple cutting tools, streamlining the fabrication process.

Minimal Heat Affected Zone (HAZ): Traditional cutting methods often introduce substantial heat into the material, leading to a heat affected zone that can cause warping, distortion, or changes in material properties. Laser cutting, particularly with advanced fiber lasers, significantly reduces the HAZ. This preservation of material integrity is crucial, especially in applications where structural strength and dimensional accuracy are paramount.

Intricate Design Possibilities: The non-contact nature of laser cutting allows for the creation of intricate designs that might be impractical or impossible with conventional cutting methods. Intricate perforations, detailed engravings, and complex contours can be effortlessly achieved, opening up creative avenues for designers and engineers.

Minimal Post-Processing: Laser-cut edges are generally smooth and free from burrs or rough surfaces, reducing the need for extensive post-processing. This not only saves time but also ensures that the final product meets high-quality standards without additional finishing steps.

Additional resources:Which Automatic Soldering System Revolutionizes Electronics Manufacturing?

The Future of Precision Cutting: Metal Plates & Fiber Laser

What are the top 5 benefits of using a big bag lifter coupon in your B2B purchase decision?

Revolutionize Your Riding Experience with AirHorse: Uncover the Best Tips and Tricks!

Is PE foam recyclable?

What are the advantages of purchasing an 800g ozone generator?

Turbocharge Your Music Production with GX-E-CS2 Compressor: The Ultimate Expert Guide!

Reduced Material Waste: Laser cutting optimizes material usage through precise cuts, which helps minimize waste. Traditional cutting methods often result in significant scrap material due to the wide cutting paths. Laser cutting's narrow kerf width translates to substantial material savings, aligning with sustainability goals.

Flexibility and Quick Prototyping: Laser cutting technology supports quick changes in design without the need for expensive tooling adjustments. This flexibility is especially valuable during the prototyping phase, allowing manufacturers to rapidly iterate and fine-tune their designs before moving into full-scale production.

Automation Integration: Laser cutting systems can be seamlessly integrated into automated manufacturing processes. This integration not only enhances efficiency but also reduces the potential for human errors, resulting in consistent and high-quality output.

Reduced Tool Wear: Traditional cutting methods involve physical contact between the cutting tool and the material, leading to wear and tear on the tool. Laser cutting's non-contact nature reduces tool wear, minimizing the need for frequent tool replacements and maintenance.

In essence, laser cutting's precision, efficiency, versatility, and ability to accommodate intricate designs make it a perfect fit for sheet metal fabrication. Its ability to address both large-scale production needs and small-scale customization requirements positions it as a transformative technology in the realm of manufacturing. As laser cutting technology continues to evolve, it is likely to further streamline and elevate the sheet metal fabrication process, enabling manufacturers to achieve greater levels of innovation and excellence.

Why is the Revolutionary Concrete Slab Making Machine Transforming Construction?

PVC Pipe Straightening: Is It Worth the Extra Effort?

Unveiling the Power of Custom Induction Heating

The Ultimate Guide to Direct Driven Air Compressors

Revolutionize Metal Design with Precision Cutting Machines - Top Solutions to Boost Productivity!

Discover the Power and Performance of Yanmar 3TNE74

Say goodbye to kinks! Discover how Rapid Air Pipe Straightener enhances efficiency with smooth airflow.

336

0

0

Related Articles

-

216

0

0

-

Torsion Tube Temper: Unlocking Increased Durability

Welcome to a groundbreaking discussion on the incredible world of torsion tube tempering!

225

0

0

-

190

0

0

-

Which cutting-edge plastic machine manufacturer is revolutionizing the industry?

Which Cutting-Edge Plastic Machine Manufacturer is Revolutionizing the Industry?

219

0

0

-

Ultimate Guide: Unleashing the Power of Metal Model Parts - Everything You Need to Know!

Ultimate Guide: Unleashing the Power of Metal Model Parts - Everything You Need to Know!

236

0

0

-

202

0

0

-

263

0

0

-

214

0

0

Comments

All Comments (0)