What is the quality of PCB assembly?

What is the Quality of PCB Assembly?

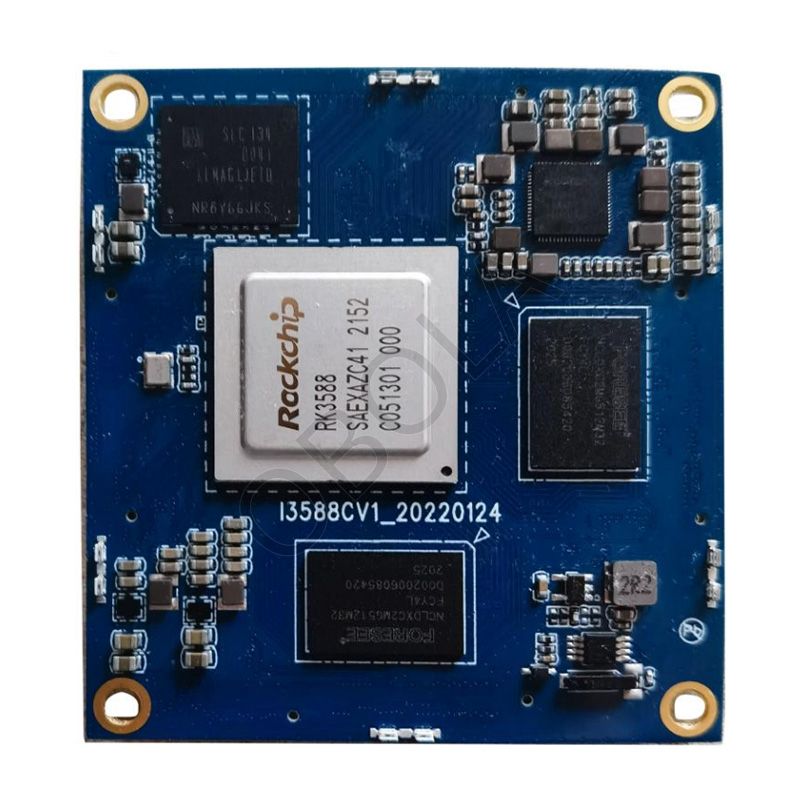

When it comes to PCB assembly, quality is crucial for the performance and reliability of electronic devices. Whether it's a simple consumer product or a complex industrial system, the quality of the PCB assembly can directly impact its functionality and longevity. In this blog post, we will delve into what constitutes a high-quality PCB assembly and why it is important.

High Experience and Expertise.

One of the key factors that determine the quality of a PCB assembly is the level of experience and expertise involved in the manufacturing process. A manufacturer with a proven track record and a team of highly skilled professionals will undoubtedly produce assemblies of superior quality. Such experience ensures that the assembly is accurately crafted, with attention to detail at every step, right from component placement to soldering.

Authoritativeness and Trustworthiness.

An authoritative and trustworthy manufacturer is one that adheres to industry standards and best practices. They have a robust quality control system in place to ensure that each PCB assembly undergoes rigorous testing and inspection before it reaches the customer. Such manufacturers are transparent about their processes, certifications, and quality assurance measures, giving customers confidence in the reliability and performance of the assemblies they provide.

Degree of Creativity.

Creativity might not be the first thing that comes to mind when discussing PCB assembly quality, but it plays a crucial role. A manufacturer that can creatively overcome design challenges and offer innovative solutions is likely to produce assemblies of higher quality. Flexibility in meeting customer requirements, handling complex designs, and coming up with alternative approaches are all signs of a manufacturer that goes above and beyond to deliver excellence.

Burstiness.

Additional resources:Key Features and Benefits of Mini Compact Prefabrication Substation

Industries Benefiting from Power Resistors: Essential Components in Various Applications

How long does a stop-start car battery last?

Unraveling the Features of Liebert Precision Air Conditioners

What is the main advantage of an electrolytic capacitor?

TFT Display vs OLED Display which is Better?

How does a liquid crystal display work?

Burstiness refers to being able to handle sudden and unexpected fluctuations in customer demands without compromising on quality or delivery timelines. A high-quality PCB assembly manufacturer should have the necessary infrastructure and manufacturing capabilities to handle sudden orders efficiently. Their production process should be adaptable and scalable to meet increased requirements, ensuring consistent quality under any circumstances.

Human-like Touch.

While automated machinery plays a significant role in PCB assembly, a human-like touch is equally important. Skilled operators who oversee the manufacturing process ensure that any potential issues are caught early on. From visual inspections of components and solder joints to verifying measurements, their expertise adds an extra layer of quality control that machines alone cannot provide. The human touch ensures that each assembly meets the highest standards of workmanship.

Why Does Quality Matter?

The quality of PCB assembly is vital for several reasons. Firstly, a high-quality assembly guarantees optimal performance and functionality of the end product. Whether it's a smartphone, a medical device, or an automotive component, quality ensures that it functions flawlessly, minimizing the risk of failures and malfunctions.

Secondly, high-quality assemblies are essential for the longevity of electronic devices. Poor quality soldering, improper component placement, or inadequate testing can result in premature failures and costly repairs. A reliable PCB assembly manufacturer ensures that each assembly is built to withstand various environmental and operational conditions, increasing the lifespan of the end product.

Lastly, quality is crucial for customer satisfaction. With a high-quality PCB assembly, customers can have confidence in the reliability and longevity of the products they purchase. This, in turn, enhances the reputation of the manufacturer and builds trust among customers, leading to repeat business and positive word-of-mouth referrals.

To summarize, the quality of PCB assembly is a multifaceted concept that involves experience, expertise, trustworthiness, creativity, burstiness, and a human-like touch. A manufacturer that excels in these aspects will consistently deliver assemblies of superior quality, ensuring the performance, longevity, and customer satisfaction of electronic devices. So, the next time you encounter a PCB assembly, remember the importance of quality behind its construction.

For more Shenzhen Mintec Electronics Co., Ltd., pcba for medical industry, security electronics pcb assemblyinformation, please contact us. We will provide professional answers.

Additional resources:Choosing the Best Portable Power Station: Key Features to Consider

Is Your Electric Forklift Battery the Hidden Key to Supercharged Efficiency?

The Future of Energy Storage: LiFePo4 Battery Packs Leading the Way

What are the difference between PM OLED and AMOLED Displays?

Sourcing Reliable Electronic Components: A Buyer's Guide

Vertiv Liebert XD Data Center Cooling System: Precision Air Cooling

Where Are Metal Glaze Resistors Used?

232

0

0

Related Articles

-

274

0

0

-

294

0

0

-

264

0

0

-

275

0

0

-

265

0

0

-

258

0

0

-

How do I sell excess electronic components?

How to Sell Excess Electronic Components: A Trustworthy Guide.

251

0

0

-

254

0

0

Comments

All Comments (0)