What is heat treatment equipment annealing?

In the realm of metallurgy and materials science, heat treatment equipment plays a pivotal role in transforming raw materials into the robust and reliable components that power our modern world. One indispensable process in this field is annealing, a controlled heating and cooling procedure that enhances the properties of metals and alloys. This article delves into the fascinating world of annealing, with a special focus on the use of medium frequency annealing equipment, exploring its principles, applications, and its indispensable role in various industries.

Understanding Annealing

Annealing is a heat treatment process that involves heating a metal or alloy to a specific temperature and then slowly cooling it down, typically in a controlled environment such as a furnace. This process imparts several key benefits to the material, including:

Stress Relief: Annealing helps relieve internal stresses and strains that might have accumulated during the manufacturing process or previous mechanical operations.

Softening: It can significantly soften the material, making it more ductile and easier to work with during subsequent processing or forming.

Recrystallization: Annealing induces recrystallization in the material, resulting in a finer and more uniform grain structure. This, in turn, enhances the material's mechanical properties such as strength and toughness.

Improving Machinability: Annealed materials are often easier to machine, cut, and weld, making them more versatile for various applications.

Enhancing Electrical and Thermal Conductivity: In some cases, annealing can improve the electrical and thermal conductivity of metals, which is crucial for applications in the electronics and energy sectors.

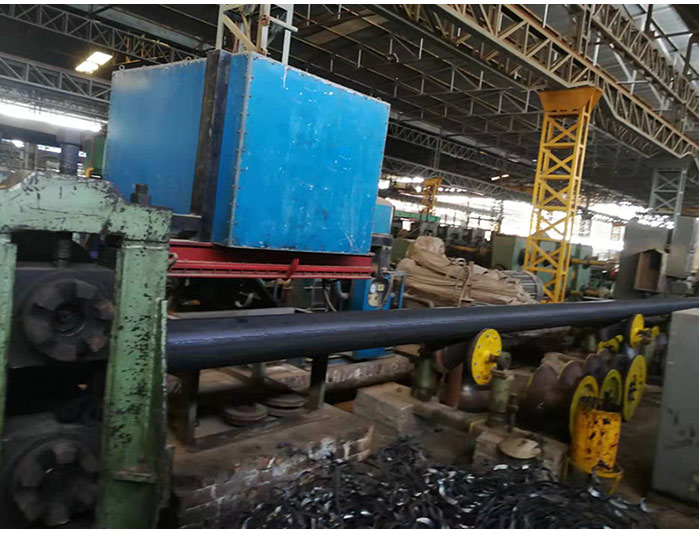

Medium Frequency Annealing Equipment

Medium frequency annealing equipment plays a pivotal role in the annealing process, particularly for materials that require precise temperature control and uniform heating. Unlike traditional annealing methods that rely on direct resistance heating or induction heating, medium frequency annealing equipment employs an intermediate frequency range, typically between 300 Hz and 10 kHz. This unique frequency range offers several advantages:

Efficient Heating: Medium frequency induction heating provides rapid and efficient heating, reducing cycle times and energy consumption compared to lower frequency methods.

Precise Temperature Control: The intermediate frequency range allows for precise temperature control, ensuring that the material reaches the desired annealing temperature with minimal variations.

Uniform Heating: Medium frequency annealing equipment is known for its ability to uniformly heat large and complex-shaped components, eliminating temperature gradients and ensuring consistent material properties.

Flexibility: It can be adapted to various materials, including ferrous and non-ferrous metals, as well as different geometries, making it a versatile choice for industrial applications.

Applications of Medium Frequency Annealing Equipment

The versatility of medium frequency annealing equipment extends across a wide spectrum of industries, each benefiting from the unique advantages it offers:

Additional resources:What are the grades of sintered filters?

How much does it cost to refill a scuba tank?

Which CNC turning machine is best?

The Future of Semicon Inspection: Revolutionizing Tech?

How do you measure radiation devices?

Revolutionizing Safety: Are Tracked Aerial Lifts Game Changers?

Unveiling the Power of Blackbird Motors Today

1. Aerospace and Aviation

In the aerospace and aviation industries, precision and reliability are paramount. Medium frequency annealing equipment plays a crucial role in the production of critical components such as turbine blades, engine parts, and structural components. The precise temperature control and uniform heating provided by this equipment ensure that these components meet stringent quality and performance standards.

2. Automotive Manufacturing

In the automotive sector, medium frequency annealing equipment is used for various applications, including the annealing of automotive springs, transmission components, and chassis parts. The enhanced machinability and improved mechanical properties of annealed materials contribute to the overall durability and performance of vehicles.

3. Electronics and Semiconductor Industry

In the electronics and semiconductor industry, where precision and consistency are imperative, medium frequency annealing equipment is employed to anneal semiconductor wafers and other electronic components. This ensures optimal electrical and thermal conductivity, contributing to the reliability of electronic devices.

4. Energy Sector

In the energy sector, medium frequency annealing equipment is utilized in the production of components for power generation and distribution. Transformer cores, electrical conductors, and various other critical components benefit from the improved electrical conductivity and magnetic properties achieved through annealing.

5. Medical Devices

The medical device industry relies on annealing for the production of surgical instruments, implantable devices, and diagnostic equipment. Medium frequency annealing equipment ensures that these devices meet stringent biocompatibility and performance requirements.

Advancements in Medium Frequency Annealing Equipment

Recent advancements in medium frequency annealing equipment have further enhanced its capabilities and efficiency. These include:

Advanced Control Systems: Modern medium frequency annealing equipment is equipped with sophisticated control systems that offer precise temperature monitoring and adjustment, ensuring consistent and repeatable results.

Energy Efficiency: Ongoing research and development efforts have led to improvements in energy efficiency, making medium frequency annealing equipment more environmentally friendly and cost-effective.

Integration with Automation: Medium frequency annealing equipment can be seamlessly integrated into automated production lines, streamlining the manufacturing process and reducing labor costs.

Remote Monitoring and Control: Some systems now offer remote monitoring and control capabilities, allowing operators to manage the annealing process from a distance, improving safety and efficiency.

Conclusion

Medium frequency annealing equipment represents a significant leap forward in the field of heat treatment. Its ability to deliver precise temperature control, uniform heating, and rapid processing times makes it indispensable in a wide range of industries. From aerospace to automotive manufacturing, electronics, energy, and medical devices, the applications of medium frequency annealing equipment are diverse and far-reaching. As technology continues to evolve, we can expect even more innovations in this field, further enhancing the efficiency and effectiveness of the annealing process and contributing to the advancement of various industries that rely on the exceptional properties of annealed materials.

What are the top tips for selecting a concrete beam cutting machine?

What is the price of 2 ton stacker?

How to ensure a successful coating line project?

Maximizing Efficiency: Full Automatic Folder Gluer Benefits

Top Tips for Using a Roller Wire Straightener

Everything You Need to Know About Blowout Prevention Systems

Is induction heating good for forging?

278

0

0

Related Articles

-

10 best longhe attachments OEM for purchase stage?

### What are the top 10 best long reach attachments OEM for purchase stage?

153

0

0

-

193

0

0

-

Unlock the Power of Vibrating Filter Sieve: Top FAQs Answered

Are you looking to unlock the power of vibrating filter sieve technology?

209

0

0

-

188

0

0

-

160

0

0

-

Top 10 X Ray Inline Inspection Buying Tips?

Are you in the market for an X-ray inline inspection system?

188

0

0

-

169

0

0

-

172

0

0

Comments

All Comments (0)