Understanding the Die Cutting Process in Custom Packaging

Die cutting is a versatile and precise process commonly used in the custom packaging industry to create unique shapes, designs, and structures. It involves the use of specialized tools, known as dies, to cut, score, or perforate materials such as cardboard, paperboard, or corrugated board. Let's delve into the key steps involved in the die cutting process for custom packaging:

Design and Prepress: The die cutting process begins with the design phase. Packaging designers create digital artwork, incorporating the desired shape, size, and structural elements of the packaging. This digital design is then prepared for printing in the prepress stage, ensuring proper alignment and color accuracy.

Die Creation: Once the design is finalized, a custom die is created. A die is a specialized tool made of sharp blades or cutting edges mounted on a sturdy base. The die is precisely crafted to match the specific shape and size requirements of the packaging design. Typically, dies are made from steel or other durable materials to ensure longevity and accuracy. Click here to learn more.

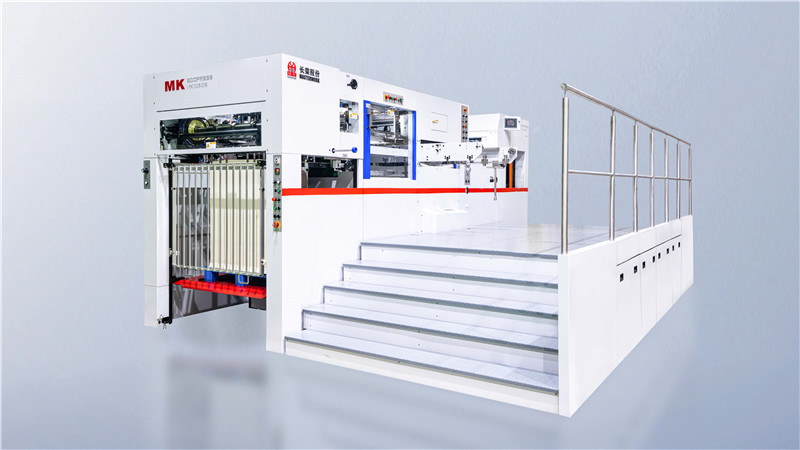

Material Preparation: The chosen packaging material, such as cardboard or paperboard, is prepared for die cutting. Large sheets or rolls of the material are loaded onto the die cutting machine. The machine's feeding system ensures a consistent supply of material for the cutting process.

Die Cutting Process: The prepared material is fed into the die cutting machine, where it comes in contact with the custom die. The machine applies pressure to force the material against the die, cutting through it according to the design specifications. The cutting edges of the die slice through the material, creating the desired shape for the packaging components.

Additional Operations: Depending on the packaging design requirements, additional operations may be performed during the die cutting process. These can include scoring, which creates fold lines for easy assembly, perforating, which creates tear lines, or embossing, which adds texture or branding elements to the packaging surface. These operations enhance the functionality and visual appeal of the final packaging.

Waste Removal: As the die cutting process progresses, waste material, known as "dust" or "chads," is generated. The die cutting machine incorporates mechanisms to remove this waste efficiently. Vacuum systems or other methods collect and dispose of the waste, leaving behind the finished packaging components.

Quality Control: Throughout the die cutting process, quality control measures are implemented to ensure accuracy and consistency. Operators check the cut pieces for any imperfections or deviations from the design. This step helps maintain the highest standards and ensures that the final packaging components meet the desired specifications.

The die cutting process plays a crucial role in the creation of custom packaging, offering endless possibilities for unique shapes, intricate designs, and efficient production. By understanding the steps involved, businesses can appreciate the precision and craftsmanship that goes into producing high-quality custom packaging solutions that captivate consumers and elevate their brand image.

446

0

0

Comments

All Comments (0)