The Versatility and Efficiency of Woven Mesh Filter Screens

Woven mesh filter screens have become an indispensable component in numerous industries, offering a wide range of applications and providing effective filtration solutions. This article explores the key features, benefits, and applications of woven mesh filter screens.

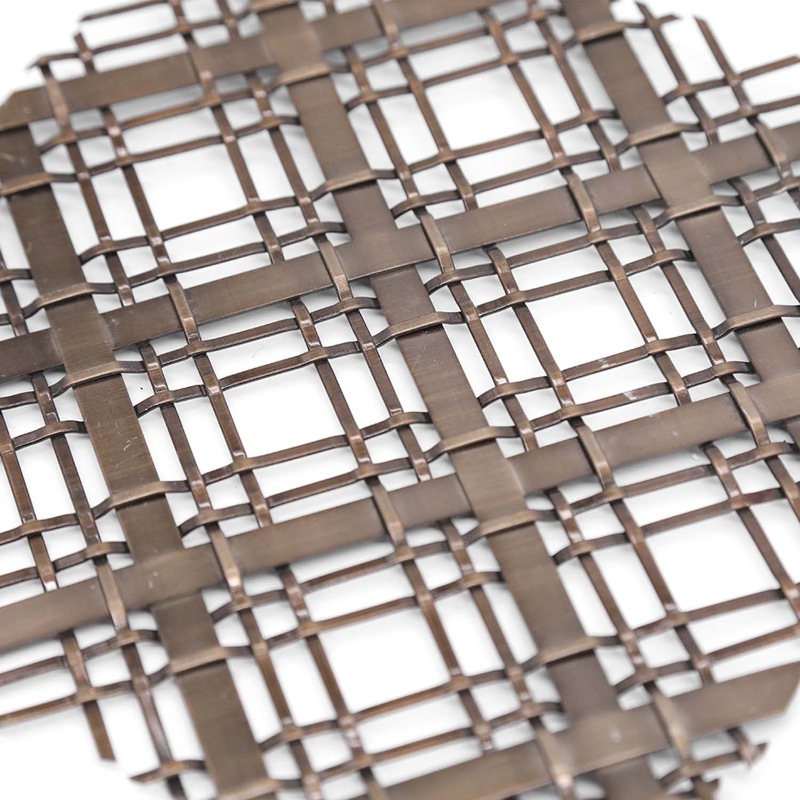

Understanding Woven Mesh Filter Screens: Woven mesh filter screens are constructed using a weaving process that interlaces individual wires to form a uniform and durable mesh structure. The mesh is available in various materials such as stainless steel, brass, or synthetic fibers, allowing customization based on specific filtration requirements.

Key Features: a. Porosity: Woven mesh filter screens offer precise control over porosity levels, ensuring efficient filtration while maintaining desired flow rates. b. Strength and Durability: The interwoven wires create a robust structure capable of withstanding high pressures, temperatures, and corrosive environments. c. Reusability: Woven mesh filter screens can be easily cleaned and reused, reducing maintenance costs and environmental impact. d. Uniformity: The consistent and uniform pore size distribution of the mesh provides reliable and accurate filtration results.

Benefits of Woven Mesh Filter Screens: a. Particle Retention: The fine and evenly spaced mesh apertures effectively capture and retain particles of various sizes, ensuring high-quality filtration results. b. Chemical Compatibility: With the availability of different material options, woven mesh filter screens can be selected to withstand specific chemical environments, maintaining compatibility and extending the lifespan of the filter. c. Versatility: Woven mesh filter screens find applications across industries such as oil and gas, water treatment, pharmaceuticals, food and beverage, automotive, and many more, highlighting their versatility and adaptability. d. Customization: The wide range of mesh sizes, wire diameters, and materials allows for tailoring the filter screens to meet specific application requirements.

Applications of Woven Mesh Filter Screens: a. Filtration and Separation: mesh filter screens are extensively used for solid-liquid separation, air filtration, gas filtration, and particle removal applications. b. Industrial Processes: They play a crucial role in protecting equipment, ensuring product quality, and maintaining process efficiency in various industries, including petrochemicals, mining, pulp and paper, and pharmaceuticals. c. Automotive Industry: Woven mesh filter screens are employed in automotive filters, preventing contaminants from entering critical engine components, improving performance, and extending the lifespan of vehicles. d. Food and Beverage Industry: These filters are utilized for food and beverage processing, removing impurities, ensuring product safety, and maintaining hygiene standards.

Maintenance and Cleaning: Proper maintenance and periodic cleaning are essential for optimal performance of woven mesh filter screens. Regular inspection, backwashing, or ultrasonic cleaning can help remove accumulated particles and ensure the longevity of the filter screens.

Conclusion: Woven mesh filter screens are a versatile and efficient filtration solution, offering precise particle retention, strength, durability, and customization options. Their widespread use in various industries highlights their importance in maintaining process efficiency, product quality, and equipment protection. With their ability to withstand demanding environments and provide reliable filtration, Changte woven mesh filter screens continue to play a vital role in numerous applications, making them an essential component in modern industrial processes.

282

0

0

Comments

All Comments (0)