Is HDPE Dredging Pipeline Worth the Investment?

Is HDPE Dredging Pipeline Worth the Investment? .

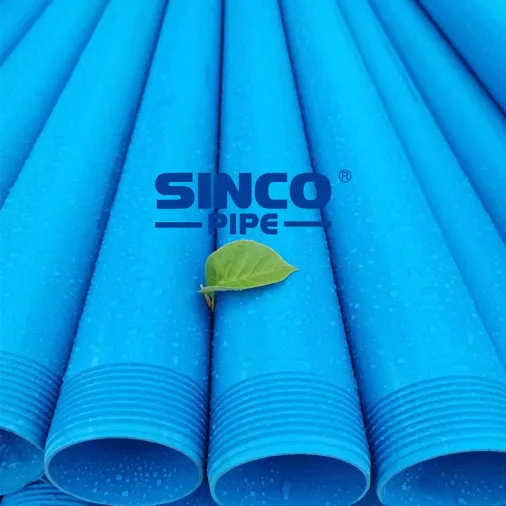

Dredging is an essential activity in maintaining and improving waterways, harbors, and ports around the world. This process removes silt, sediment, and other debris that accumulate over time, ensuring smooth navigation and preventing flooding. As technology advances, so does the equipment used in dredging operations. One significant development in recent years is the use of HDPE (High-Density Polyethylene) pipelines for dredging purposes. In this blog post, we will explore the benefits of investing in HDPE dredging pipelines and why they are worthy of serious consideration.

First and foremost, HDPE dredging pipelines offer exceptional durability. When compared to traditional materials like steel or concrete, HDPE has proven to be much more resistant to abrasion, corrosion, and chemical damage. This fact makes HDPE pipelines an ideal choice for demanding dredging operations that involve aggressive and corrosive environments, such as saltwater or chemical-rich sediments. By investing in HDPE dredging pipelines, operators can enjoy extended operational lifespans and a significant reduction in maintenance and replacement costs.

Another advantage of HDPE dredging pipelines is their flexibility, which allows for easier installation and maneuvering. The high flexibility of HDPE pipes enables them to withstand uneven ground conditions and absorb external stresses caused by movements of the surrounding environment. This flexibility also allows for easier deployment and retrieval of pipelines in different locations, making HDPE a preferred choice for portable dredging projects.

The lightweight nature of HDPE pipelines is also worth noting. HDPE pipes weigh considerably less than traditional materials, such as steel. This reduced weight facilitates transportation and handling, making it easier and cost-effective to move pipes to various dredging sites. The lightness contributes to enhanced work efficiency, as less labor is required for installation or relocation. Moreover, the lightweight property allows for longer pipeline lengths to be deployed, reducing the need for multiple joints and consequent leakage risks.

Additional resources:Discover the Game-Changing UHMWPE Mining Pipes for Sale: Unleashing Efficiency & Durability!

What does MDPE mean in pipe?

What plastic is best for CNC machining?

What is neoprene rubber used for?

How do you keep rubber hoses from cracking?

The Ultimate Guide to PTFE Film Rolls

Which is better UHMW or HDPE?

One of the defining characteristics of HDPE dredging pipelines is their smooth interior surface. HDPE pipes have a low friction factor, greatly reducing the resistance to flow of slurry and sediments through the pipelines. As a result, slurry transportation becomes more efficient, enabling higher pumping rates and energy savings. The smooth lining also minimizes the risk of clogging, ensuring uninterrupted dredging operations. This advantage is particularly valuable in projects where the material being dredged has a higher concentration of solids.

In addition to its many other benefits, HDPE is also a highly sustainable choice for dredging operations. HDPE is a recyclable material, and it can be easily reprocessed into new products after the pipelines have served their intended purpose. By investing in HDPE dredging pipelines, operators can contribute to a cleaner and greener planet. Furthermore, HDPE has a much lower carbon footprint compared to other materials. By choosing HDPE over steel or concrete, dredging companies can significantly reduce their environmental impact and comply with sustainability goals.

To ensure the success of any dredging operation, it is crucial to choose a reliable and reputable supplier for HDPE dredging pipelines. Not only must they provide high-quality products, but they must also possess the necessary expertise and experience to offer comprehensive support during the project. Advanced suppliers understand the intricacies of each dredging operation and can provide tailor-made solutions that meet the specific requirements of the project. They can assist with pipeline design, offer installation guidance, and provide ongoing technical support, ensuring optimal performance and longevity of the HDPE dredging pipelines.

In conclusion, the investment in HDPE dredging pipelines is undoubtedly worth considering for any dredging project. The durability, flexibility, lightweight nature, smooth interior surface, sustainability, and expert support provided by HDPE pipelines make them an ideal choice for a wide range of dredging applications. By embracing HDPE pipelines, operators can improve efficiency, reduce downtime and maintenance costs, while promoting sustainability. As we witness the ever-growing demand for maintenance and expansion of waterways, investing in HDPE dredging pipelines is a wise and forward-thinking choice.

If you are looking for more details, kindly visit hdpe pipes for sale, can hdpe pipe be used for hot water, hdpe pipe used for.

Additional resources:What are the disadvantages of HNBR?

What is the price of HDPE pipe grade?

Revolutionizing Manufacturing: The Power of Engineering Plastics

HDPE Pipe vs PVC Pipe: Which is the Future of Plumbing?

What is the coefficient of roughness for HDPE pipe?

How do you choose plastic material for injection molding?

Which mat is best for cow?

208

0

0

Related Articles

-

Enhance Your Style: Vibrant O-Ring Color Dots

Google Hot Topics: Enhance Your Style: Vibrant O-Ring Color Dots?

224

0

0

-

220

0

0

-

258

0

0

-

247

0

0

-

247

0

0

-

242

0

0

-

265

0

0

-

241

0

0

Comments

All Comments (0)