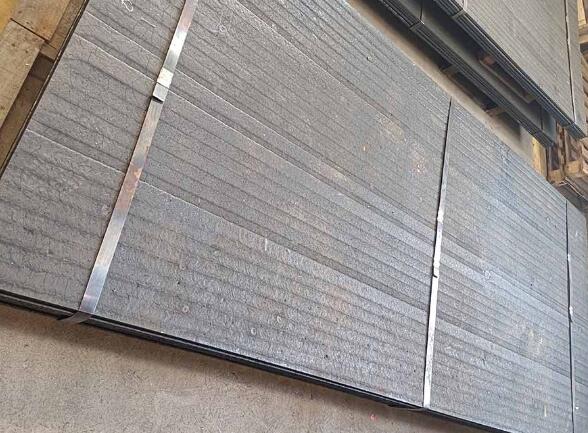

What Are The Reasons for Failure of Wear Plates?

The three major failure modes of wear plate materials are: wear, fracture, and corrosion. And the failure mode of wear-resistant castings is wear, fracture, deformation and other major failure modes.

1. Wear loss effect

Wear loss is the main way of failure of all metal surfaces such as wear plates, especially in the strong abrasive wear, wear-resistant steel is gradually worn and eventually fails. The hardness of wear-resistant steel is an important factor affecting its wear.

Generally speaking, the hardness of wear-resistant parts is more than 1 times higher than the hardness of the material to obtain better wear resistance, which is the hardness of the working surface of the wear-resistant parts after wear and not the initial hardness before wear. But not the higher the hardness the better, because the higher the hardness the more brittle the wear parts are and the easier to fracture.

2. Fracture failure

The fracture of the wear plate is often the result of a large impact during its use. If the wear parts are not installed properly, such as the back of the liner is not in contact with the cylinder when it is installed, it is very easy to produce fracture. To improve the impact degree and toughness of the wear parts and reduce their crack expansion speed will be beneficial to anti-fracture. And at present, the surfacing type wear-resistant material has replaced the wear-resistant casting products.

3. Deformation failure

Deformation failure is the wear plate yield strength is low, so that in the process of use by external force and serious macro plastic deformation occurs, the shape of the casting changes and failure. Failure is mostly seen in the wear-resistant manganese steel parts with low yield strength, such as the ball mill working conditions of large impact, manganese steel liner plate serious anti-bow deformation can pull off the bolt or make the liner plate dislocation and fall off.

Understanding the causes of failure of wear-resistant parts will be a guide to choosing the right wear-resistant steel plate for the working conditions. We are a wear plate supplier. If you are interested in our products, please contact us now!

325

0

0

Comments

All Comments (0)