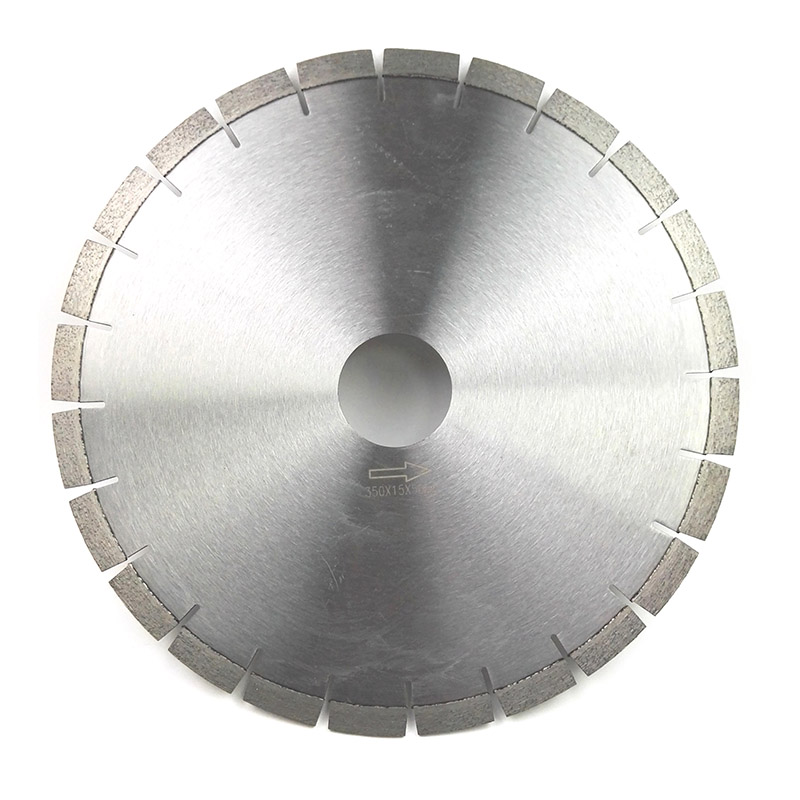

Why are diamond blades so cheap?

While diamond blades can be essential tools for cutting a variety of hard materials, the market does offer options at different price points. The perceived affordability of some diamond blades may be influenced by several factors:

1. Segmented vs. Continuous Rim Blades:

Segmented diamond blades, featuring gaps between the diamond-encrusted segments, are generally more affordable than continuous rim blades. Continuous rim blades provide a smoother cut but are often pricier due to the continuous layer of diamonds.

2. Manufacturing Techniques:

The manufacturing techniques and materials used can impact the cost of diamond blades. Blades produced using lower-cost methods or less expensive diamond grit may be more budget-friendly but could also have limitations in terms of durability and performance.

3. Diamond Quality:

The quality of the diamonds used in the blade's composition plays a significant role in pricing. Lower-cost diamond blades may use synthetic or lower-grade diamonds, affecting their cutting efficiency and overall lifespan.

4. Application Specificity:

Diamond blades are designed for specific applications, and more affordable options might be suitable for less demanding tasks. If a blade is intended for occasional use on softer materials, it may be priced lower than blades designed for heavy-duty or professional applications.

5. Bonding Material:

The bonding material that holds the diamonds in place also influences the cost. Some budget-friendly diamond blades may use bonding agents that are less expensive but may wear out more quickly during use.

Additional resources:Which Factors Drive the Surging Tricone Drill Bit Prices?

Which Liquid Gas Pump is the Ultimate Money-Saver?

Which Steel Body PDC Bit Manufacturers Offer the Best Prices and Quality?

Which Non Sparking Ratchet Wrench with Retractable Handle offers the best value for money?

What is the difference between milled-tooth bit and insert bit?

Exploring TCI Drag Bits: Enhancing Drilling Efficiency & Durability

Which Hydraulic Test Bench Should You Choose?

6. Brand Reputation:

Established and reputable brands in the industry may offer higher-priced diamond saw blades due to their commitment to quality, research, and development. Lesser-known or generic brands may provide more budget-friendly options but could vary in terms of quality.

7. Competition and Market Trends:

The competitive nature of the market can contribute to variations in diamond blade prices. Manufacturers may adjust prices based on market demand, competition, and current trends in the industry.

8. Bulk Purchases:

Purchasing diamond blades in bulk may result in lower per-unit costs. Some suppliers or retailers offer discounts for larger quantities, making it more economical for consumers who require multiple blades.

9. Regional Variances:

Prices of diamond blades can vary regionally based on factors such as manufacturing costs, transportation, and distribution. Local market conditions and supplier competition can influence the affordability of these tools.

10. Marketing and Sales Strategies: - Sales promotions, discounts, or clearance sales may contribute to the perception of affordability. Some suppliers use strategic marketing and sales tactics to attract customers with competitive pricing.

It's crucial for buyers to balance cost considerations with their specific cutting needs. While more affordable diamond blades may suit certain applications, investing in higher-quality blades from reputable brands might be justified for demanding or professional tasks where durability and precision are paramount. Understanding the specific requirements of the cutting job and selecting a diamond blade accordingly can lead to a more cost-effective and satisfactory outcome.

Non-Sparking Box End Wrenches: Which Revolutionizes Workplace Safety?

Down the Hole Bits: How to Revolutionize Drilling Technology?

Choosing the Right Tie Wire Twist Tool

What can I use instead of circlip pliers?

Master the Art of Forming Metal: Discover the Top Industrial Sheet Metal Benders

Advantages of Cordless Drill Drivers

What is the process of rotary drilling?

195

0

0

Related Articles

-

232

0

0

-

Which gaz booster provides the best value for purchase stage?

Which gas booster provides the best value for the purchase stage?

177

0

0

-

117

0

0

-

How many PSI is a hydraulic pump?

A hydraulic pump typically operates at a pressure of around 2500 to 3000 PSI.

162

0

0

-

Essential Guide: Non-Sparking Double Open End Wrench

Welcome to our comprehensive guide to Non-Sparking Double Open End Wrenches.

119

0

0

-

133

0

0

-

Which Soft Formations TCI Bit Works Best for Efficient Drilling in Modern Times?

Which Soft Formations TCI Bit Works Best for Efficient Drilling in Modern Times?

165

0

0

-

135

0

0

Comments

All Comments (0)